System Control

Configuring instead of programmingSTEIN takes control of the production processes and the communication to the workstations with our system control. The sophisticated and proven control has been on the market for more than 25 years and delights its users through easy operation and flexibility. Order management, product management and especially the workflow can be easily created and changed without SPS programming knowledge. Especially in times of Industry 4.0 the vertical integration through STEIN System Control has been possible for many years (ERP/MES).

Efficient control for your production line

Benefit from the easy configuration

STEIN system controls include production relevant functions, which are key to your success. The all inclusive STEIN LOGISTIC can be used for each production type and is based on an innovative configuration of each module such as:

- Product management

- Order management

- Workflows

Successful STEIN users configure their system according to their individual needs. Analyses in the phases maintenance, commissioning as well as data transfer to higher-level systems are „daily work“.

Control Philosophy

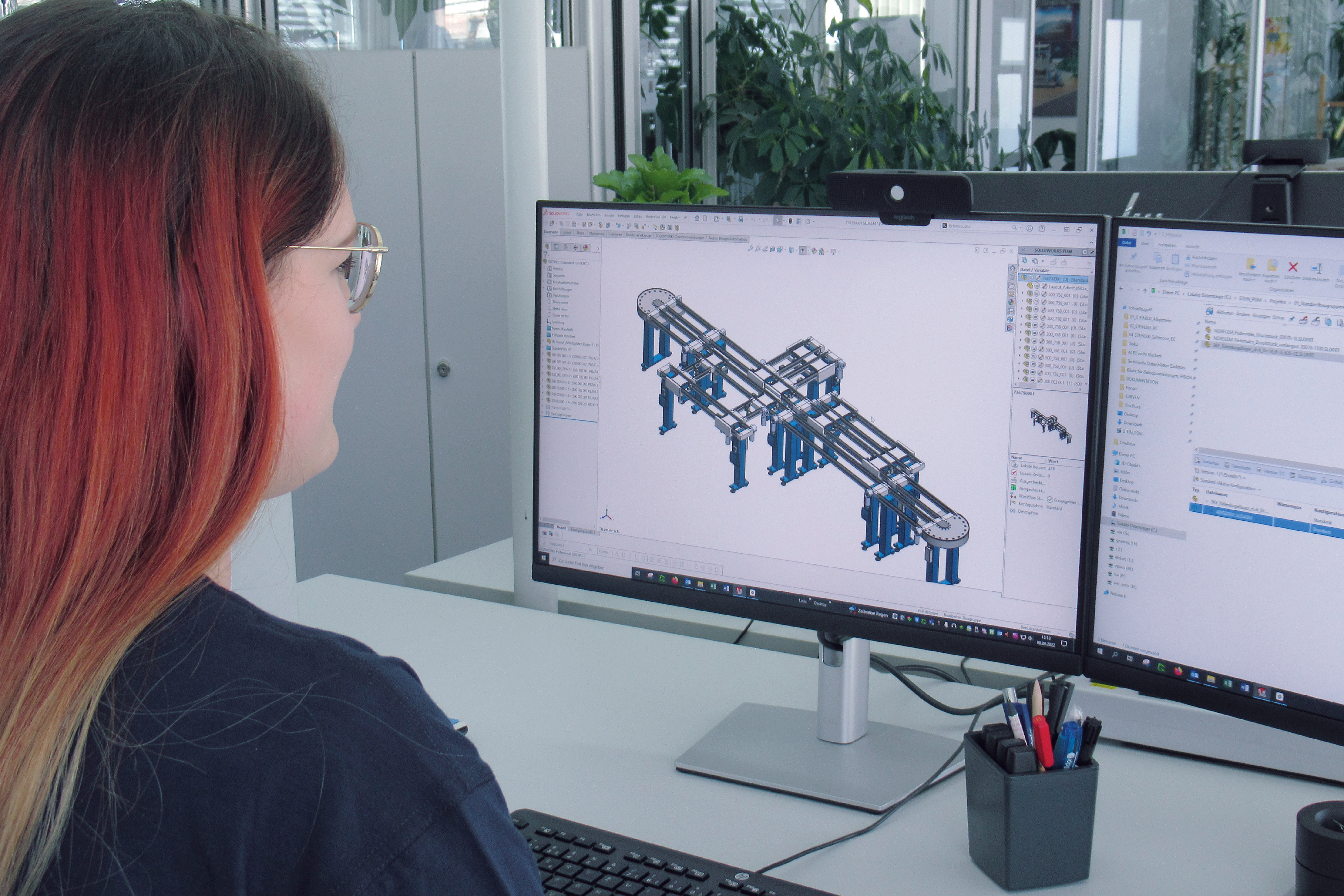

The flow of materials made possible by an efficient system is the lifeline of a successful production operation. However, a system can only be as efficient as its controls. For this reason, there is more than just a clever design and good software behind the STEIN 300 system controls – they are the product of a philosophy that STEIN applies to all of its systems: to make work easier for customers and go the crucial extra mile in development. As a result, STEIN controls are prepared for almost any change, conversion or expansion that may take place in a production process over the years. Thanks to our many years of experience in developing interfaces with mechanical engineering companies, our customers can rest assured that choosing STEIN is the right decision when it comes to controls as well as components. Every transfer system we supply is commissioned and tested at STEIN and accepted by the customer on our premises. This means that every system is tested and delivered in working order. Clever customers think ahead – with controls that are prepared for any eventuality and are extremely easy to operate.

Efficient service package for your control system

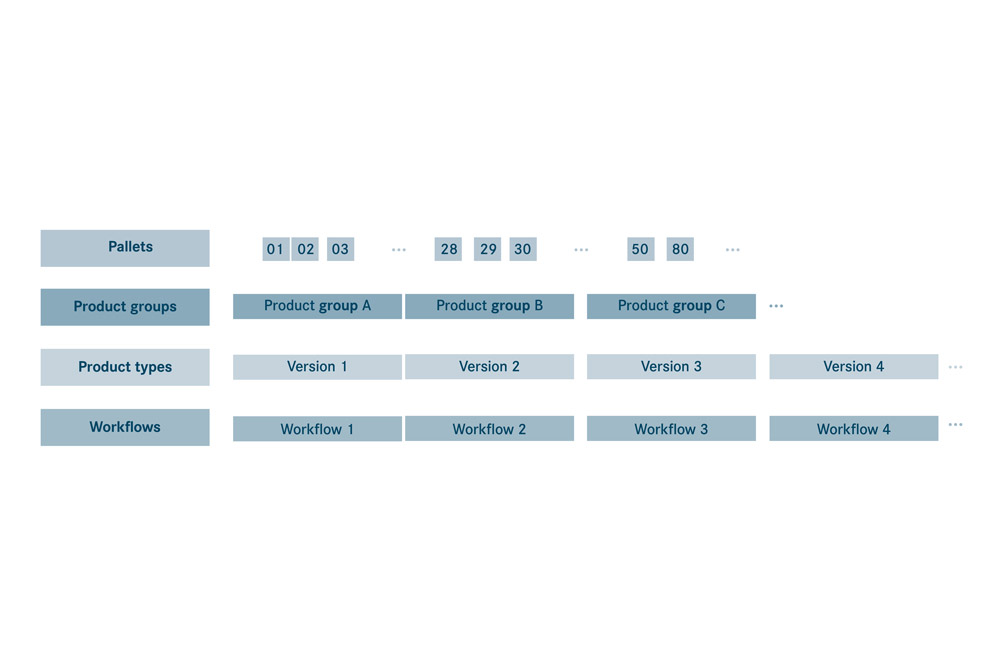

Product Management

From mixed production lot size 1 to pure series production, each product can be created and supplemented with additional parameters via the product management.

Workflows can be attached to each product to include the individual route in case of an order. Product parameters can be easily output at the workstations – variants (e.g. connector type, colour).

This gives you the necessary flexibility in the age of Industry 4.0 to map your product portfolio individually.

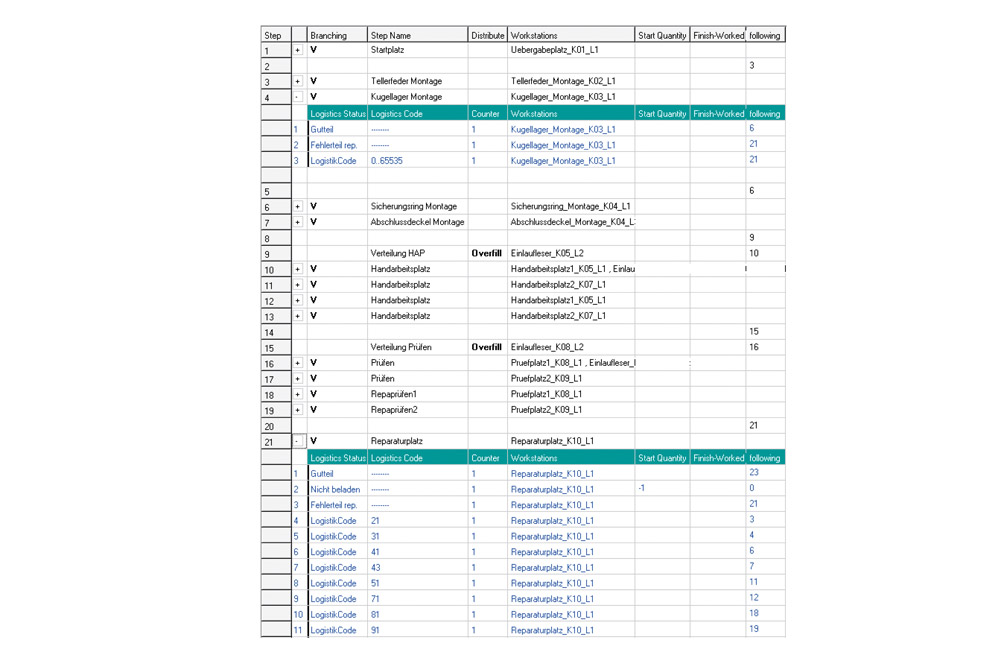

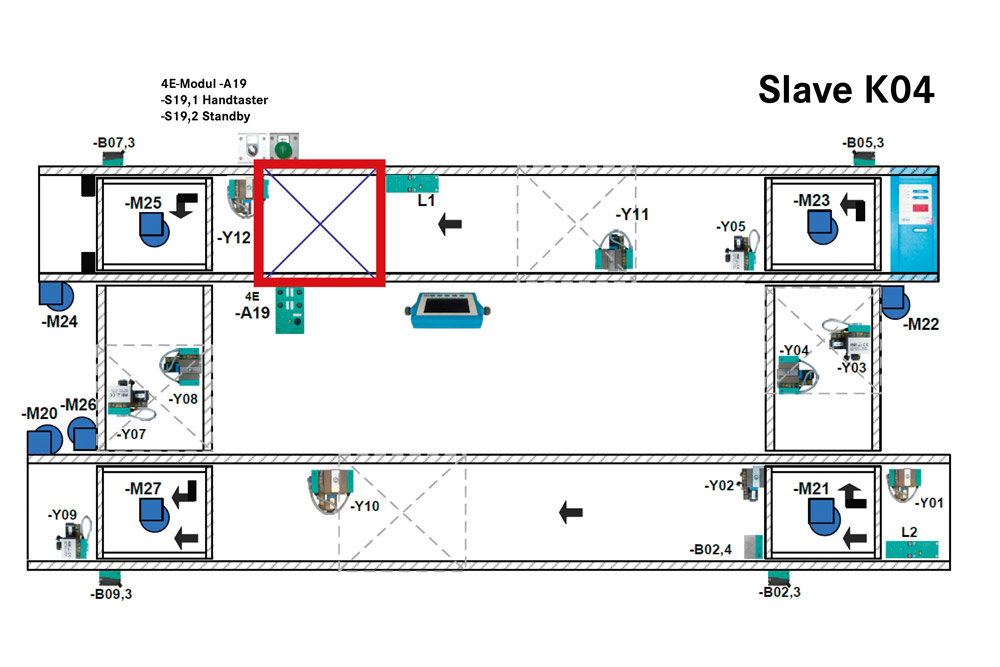

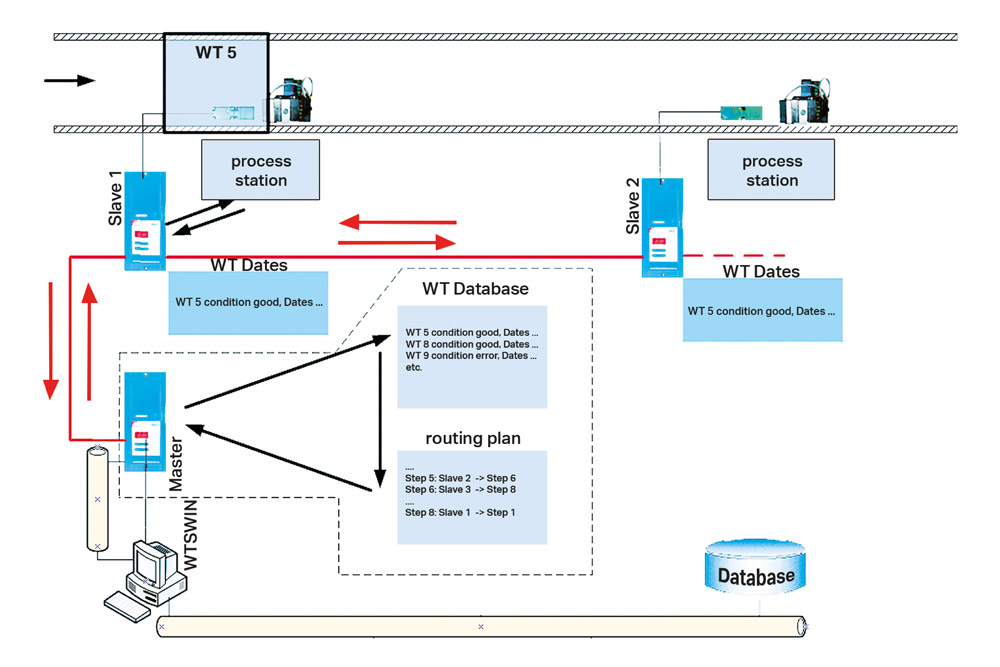

Workflow

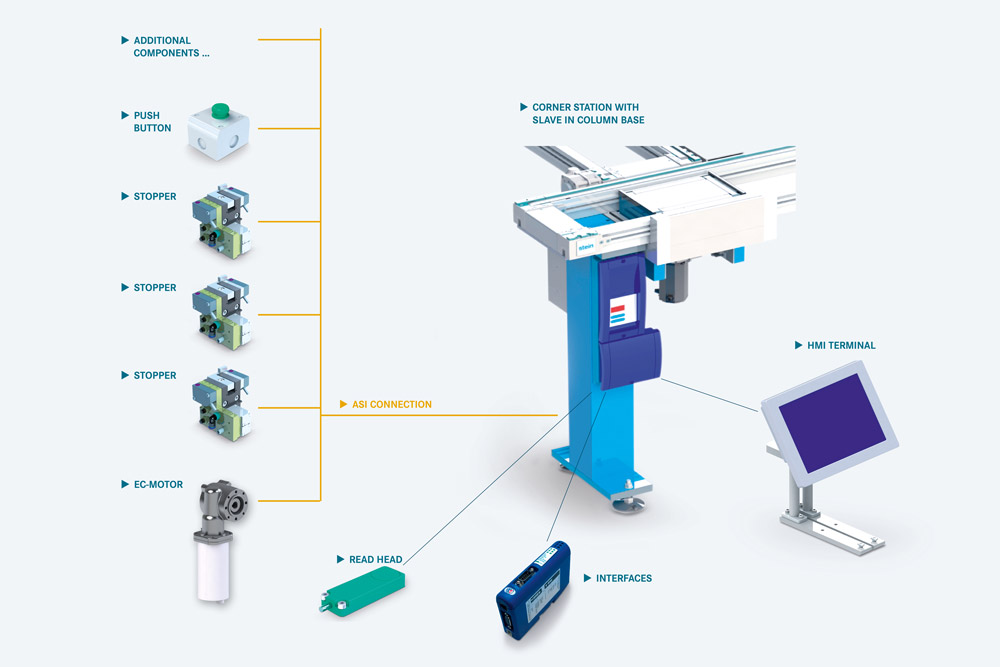

The heart of the control system is the Workflow. Here you can configure production processes without any programming knowledge. Depending on the result of the work station, the pallets with your product moves to the next desired station. The RFID technology in the STEIN system is used for unique identification of the workpiece pallets. Data are stored decentrally in the master. In addition to the classic “moving from station to station”, STEIN is also capable of process-oriented transport. Here, the station reports which process it is set up for. In the process-oriented Workflow, instead of traveling to a station a process e.g. winding wire thickness 2 is the target.

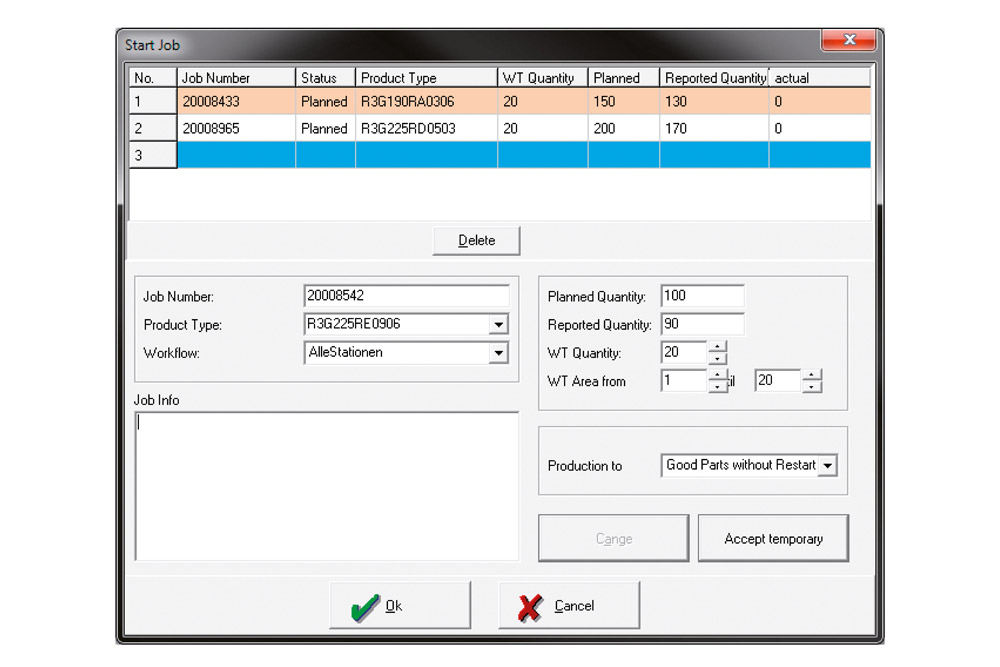

Order Management

The order control offers the user the ability to start, stop and delete jobs. These can be processed as single, parallel or endless orders. In addition to the classic order parameters, signal numbers can be defined or the number of the pallets per order can be assigned.

Diagnostics

STEIN visualizes the status of the individual conveyor controls in a simple and meaningful way via the diagnostics package. In addition, the status of each control is displayed on the control itself. In the event of service, the user can see what the status is and effectively solve the problem with the help function.

The production of the future. What determines a STEIN system control?

In times of Industry 4.0, production is changing systematically. Topics such as batch size 1, product variance, networking, process oriented production steps are important requirements that a transfer system must fulfill in the future. It is important to consider processes as a whole when converting them. Here STEIN has already implemented many solutions and is working on many more.

Quickly implemented

Start small and let your transport system grow.

Easy to configure

If desired you can basically simply configure everything yourself.

Reliable

For more than 50 years our transport systems stand for reliable production lines.

Expandable

We deliver all relevant modules of a production line from one source.

Flexible

From small work pieces up to heavy weights you will find the matching STEIN transport system.

Networked

Make and end with island solutions. STEIN systems are completely networked.

Service optimized

You determine how much service and how much personal contribution you like.

Established

System integrators know and value STEIN Automation.

Short delivery

We can ship components within 4 to 6 weeks.

Automation and logistics for the industry of tomorrow

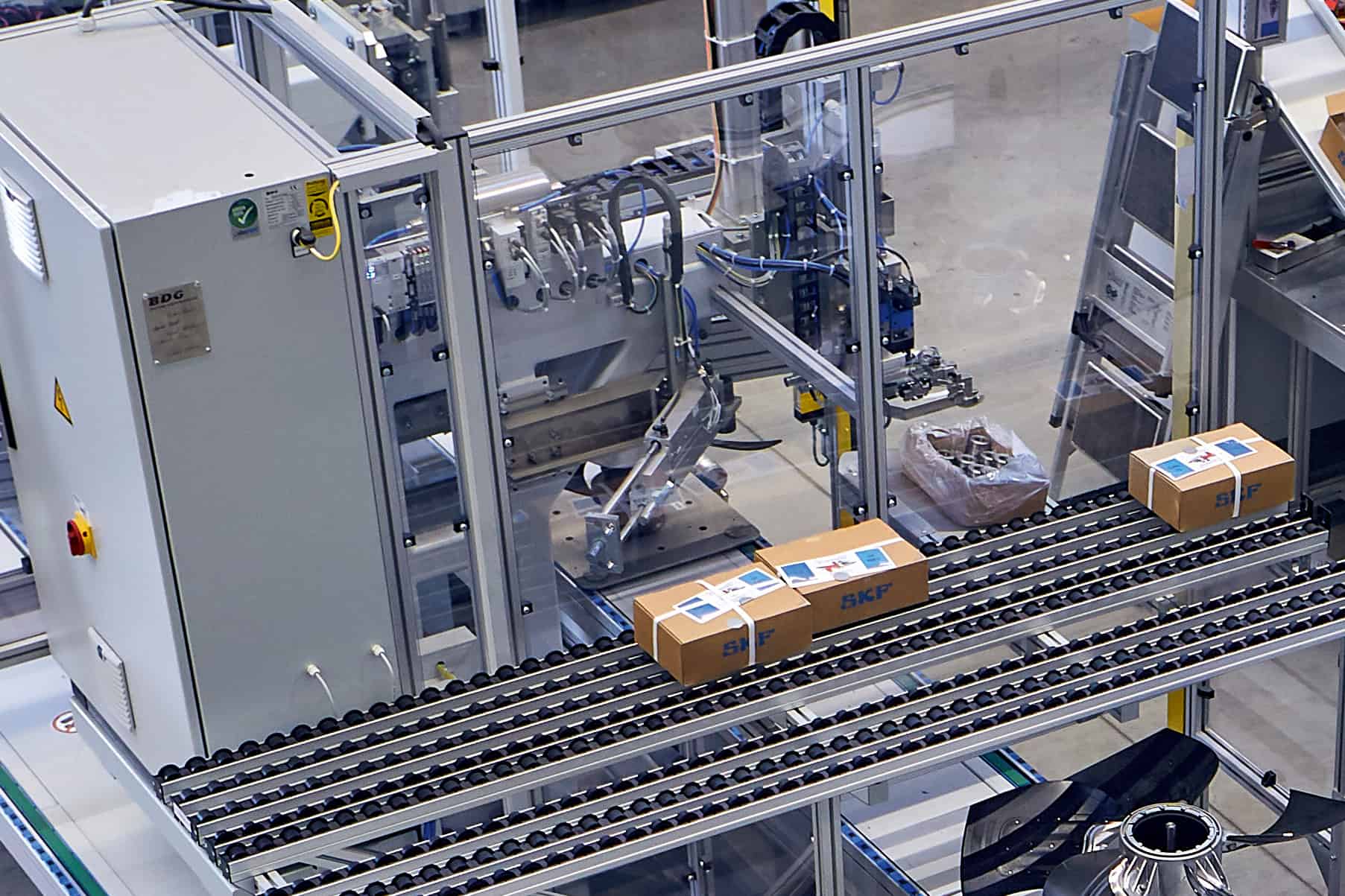

In logistics, which has strongly influenced our portfolio since 1992, STEIN has set a cornerstone for Industry 4.0. With our logistics control, we are distributing our many years of logistics and data processing knowledge since 1992. Networked production systems are controlled intelligently using RFID-technology.

- Noise reduction by SOFTMOVE up to 75%

- Energy savings of up to 80% with SOFTMOVE

- Flexibility through height-adjustable manual workstations – 100%

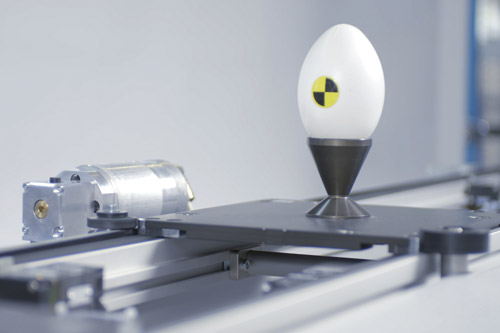

STEIN 300

In over 3,900 assembly facilities STEIN 300 has its firm place in production. At a variety of customers and in various configurations.

STEIN 300e

Instead of pneumatics, the stoppers, transfer units and centering units are controlled with electrical drives in STEIN 300e.

STEIN 400

Especially heavy and demanding tasks are handled by STEIN 400. Large work pieces with up to 80 kg in weight are transported effortlessly.

STEIN Control

The well-engineered control system without special SPS programming knowledge inspires the users by simple operation and flexibility.

Softmove

Thanks to SOFTMOVE, we transport our customers’ products from station to station very gently and with maximum energy efficiency.

STEIN LEAN

With STEIN LEAN you can process your production cycle completely from start to finish in one flow.

Modular system

With the STEIN modular system you can choose your ideal size from a pallet size of 160 x 160 mm.

Downloads

In our download area you will find CAD drawings, documentation and further information material on STEIN products.

+49 7728 64485 - 0

Johann-Liesenberger-Straße 7

78078 Niedereschach

Germany

Contact

Write to us, because together we can achieve a lot.