STEIN Control

Configuration instead of programmingEfficient service package for your logistics

Benefit from the simple configuration

The STEIN CONTROL includes production relevant functions that are decisive for your success. The all-encompassing STEIN CONTROL can be applied to every type of production and is based on an innovative configuration of the individual modules such as

- Product Management

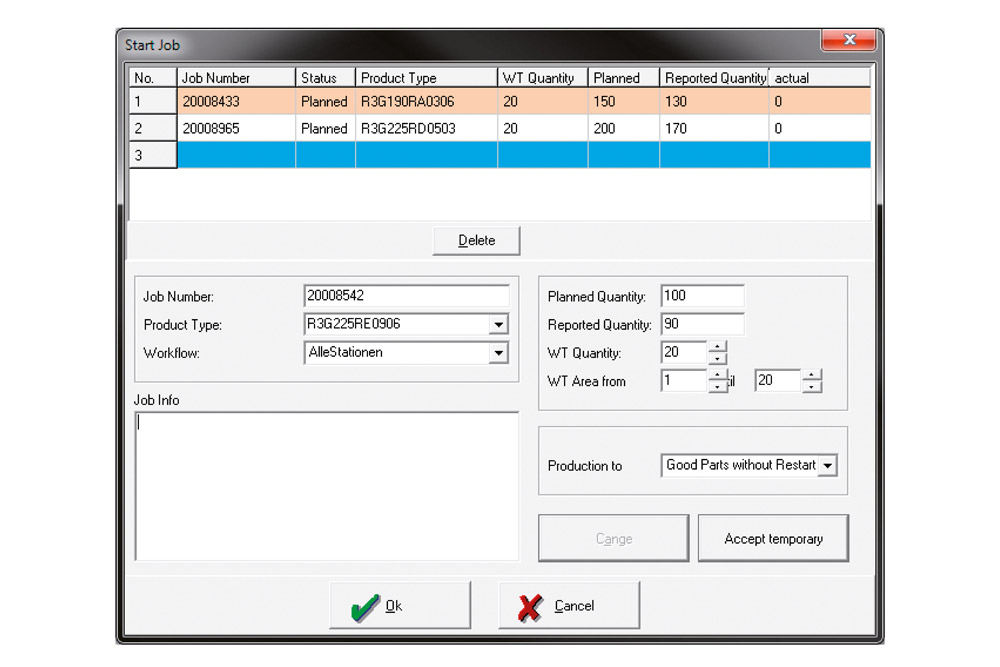

- Order Management

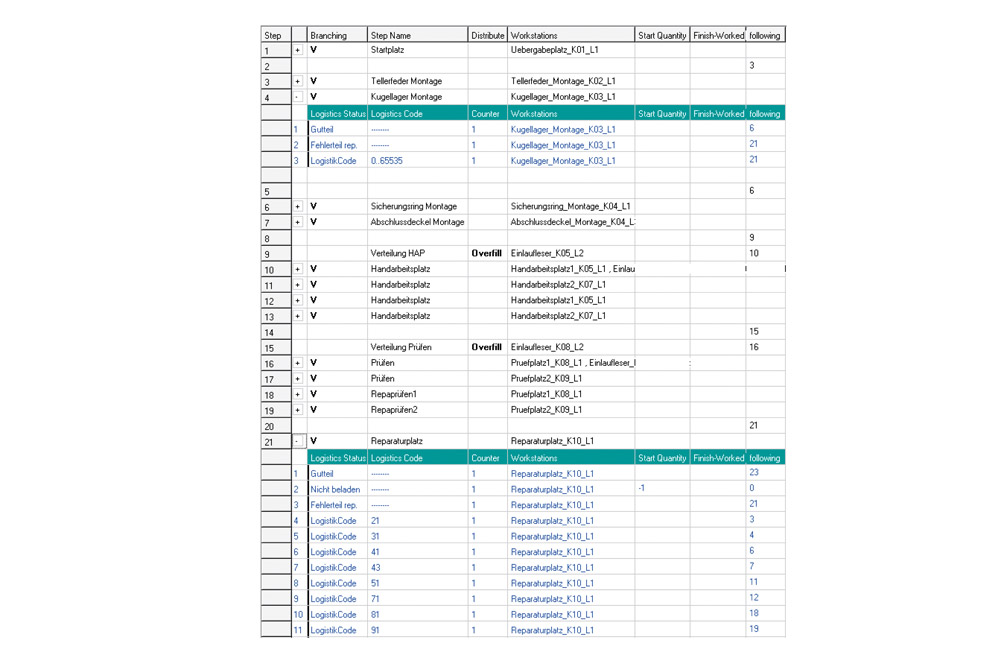

- Workflows

Successful STEIN users configure their line according to their individual needs. Evaluations in the phases of maintenance, commissioning and data transfer to superordinate systems are “daily work”.

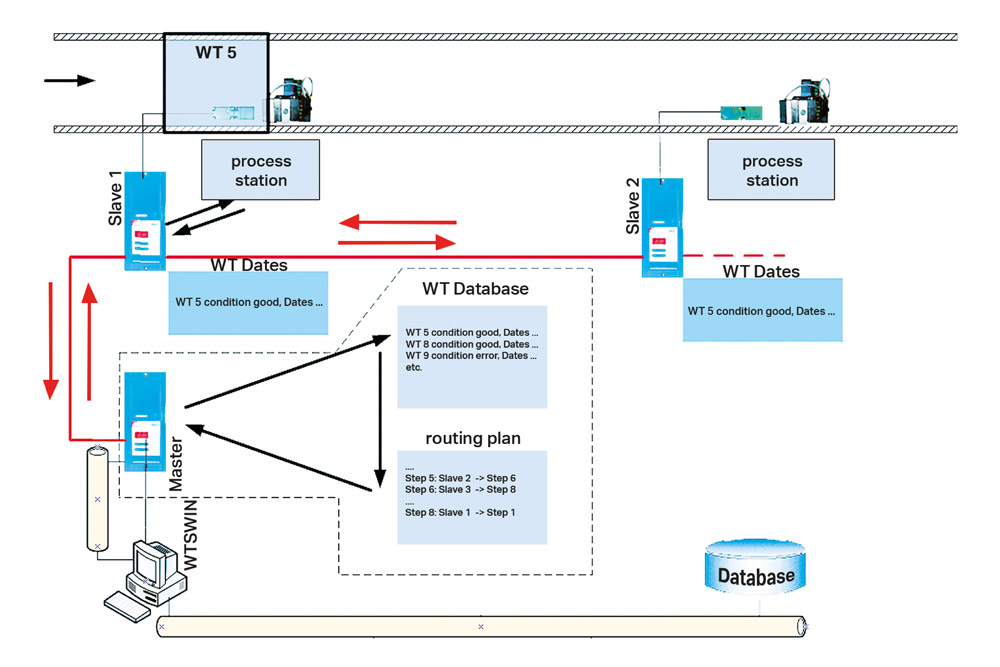

Control Philosophy

For this reason, there is more than just a clever design and good software behind the STEIN 300 system controls – they are the product of a philosophy that STEIN applies to all of its systems: to make work easier for customers and go the crucial extra mile in development. As a result, STEIN controls are prepared for almost any change, conversion or expansion that may take place in a production process over the years. Thanks to our many years of experience in developing interfaces with mechanical engineering companies, our customers can rest assured that choosing STEIN is the right decision when it comes to controls as well as components. Every transfer system we supply is commissioned and tested at STEIN and accepted by the customer on our premises. This means that every system is tested and delivered in working order. Clever customers think ahead – with controls that are prepared for any eventuality and are extremely easy to operate.

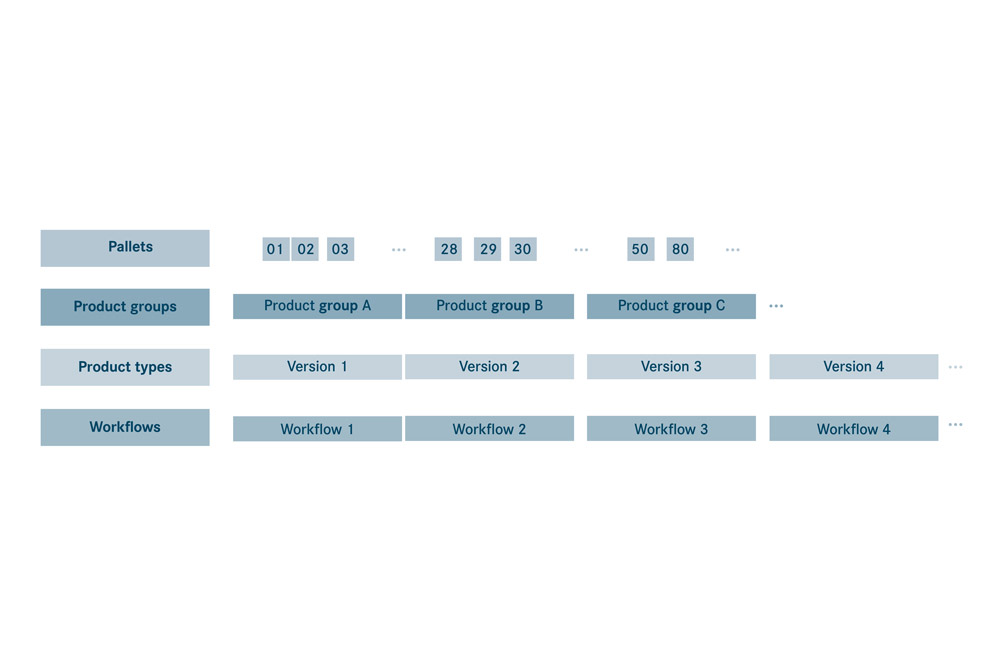

Product Management

Workflows can be attached to each product to include the individual route in case of an order. Product parameters can be easily output at the workstations – variants (e.g. connector type, colour).

This gives you the necessary flexibility in the age of Industry 4.0 to map your product portfolio individually.

Workflow

Order Management

In addition to the classic order parameters, signal numbers can be defined or the number of the pallets per order can be assigned.

Diagnostics

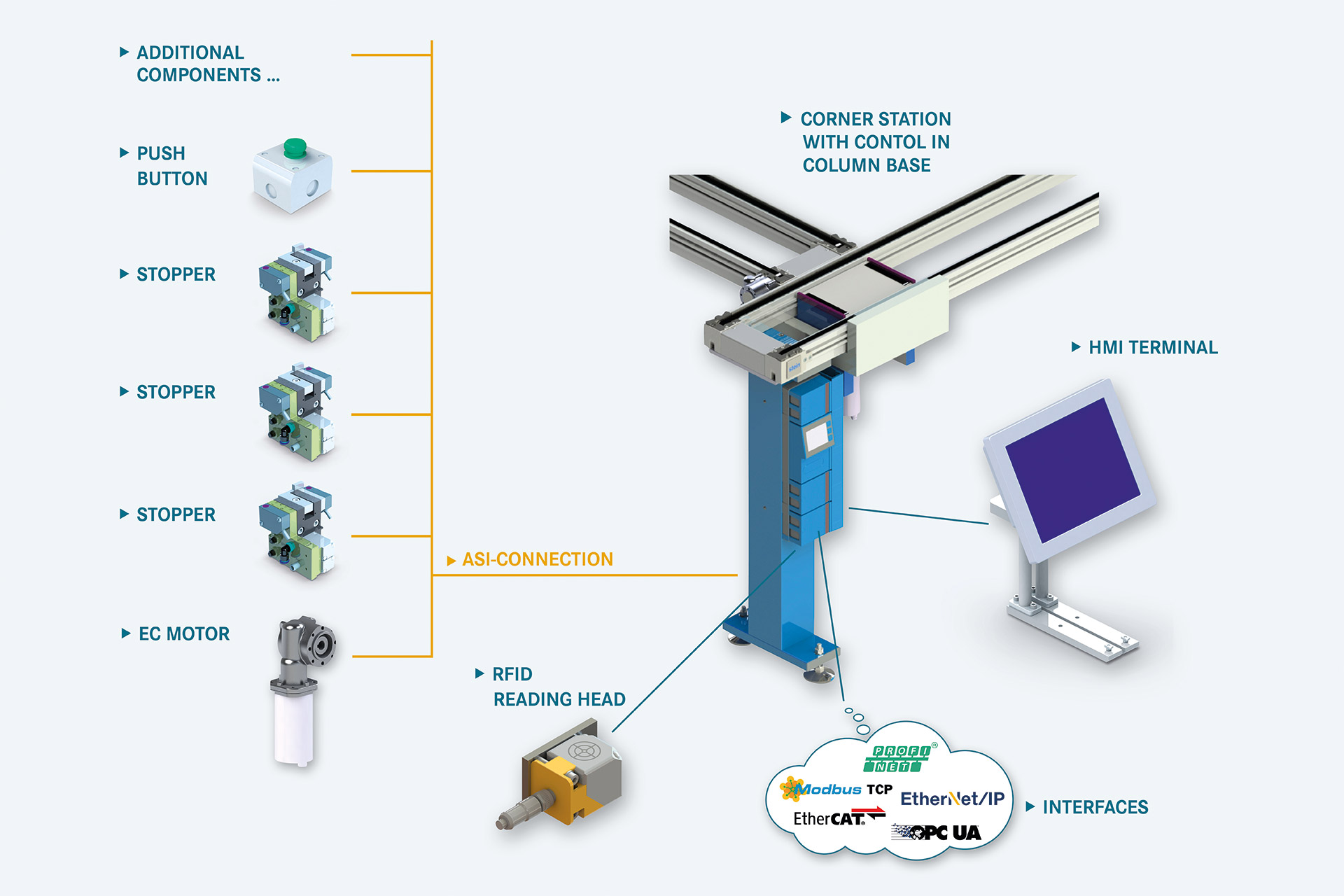

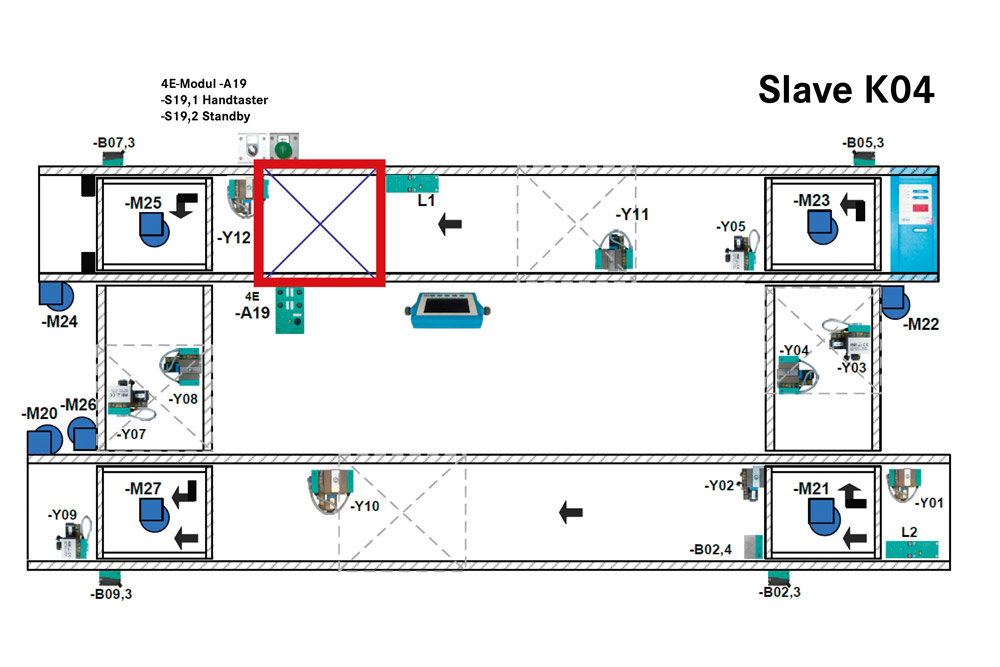

STEIN 300

The STEIN 300 has a fixed place in over 3,900 assembly halls. With a vast range of customers and in a wide variety of configurations.

From a simple circuit right through to ERP connection or traceability functionality, each installation is custom-made for our customers using a standard toolkit.

STEIN 300e

STEIN promotes the trend towards electrification with the STEIN 300e, which is based on the STEIN 300. Instead of pneumatics, the stoppers, transfer units or centering devices are controlled via electric drives. This is particularly a big advantage for cleanroom applications. As a side benefit, your production is more environmentally friendly.

STEIN 400

Despite the heavy parts, configuration and control of the system is still easy with tried-and-trusted STEIN CONTROL Solution.