STEIN link

The new STEIN intralogistics concept

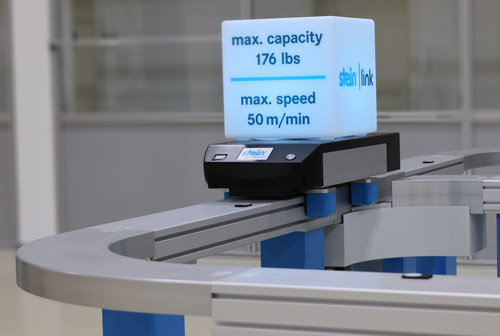

The battery-powered shuttle system combines a simple, wireless track with intelligent shuttles. With a speed of up to 50 m/min, the shuttles transport up to 80 kg (176 lbs) of payload without impact.

The new STEIN INTRALOGISTICS concept

BEYOND TRANSFER

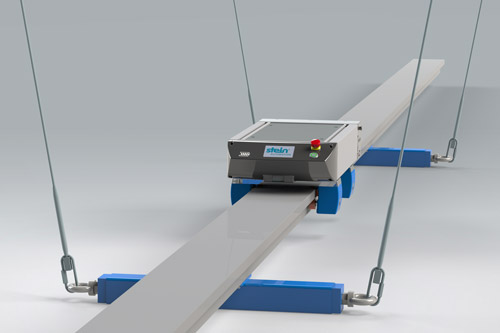

The STEIN link® shuttle system is the logical extension of the STEIN transfer systems. It combines the assembly processes in the transfer system with internal transport. STEIN link® is perfectly suited to cover long distances – on the floor, on the wall or under the ceiling to save floor-space. It can transport a wide variety of products on the pallet or as bulk material in transport boxes.

BATTERY POWERED

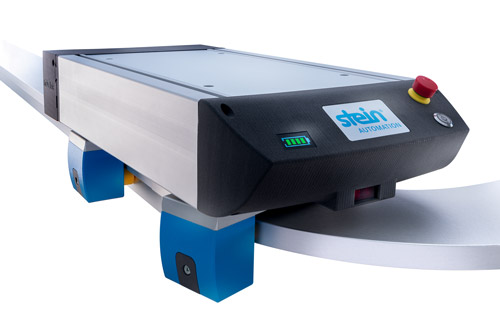

Each STEIN link® Shuttle has an easily exchangeable battery, which can be easily changed manually or fully automatically. This results in several advantages for the overall system. On the one hand, the track can be kept simple and cost-effective, as no complex electrical wiring is required. Secondly, the charging time does not affect the cycle time and availability of the shuttles. In addition, this makes the overall system extremely reliable with low maintenance.

STABLE AND SHOCKPROOF

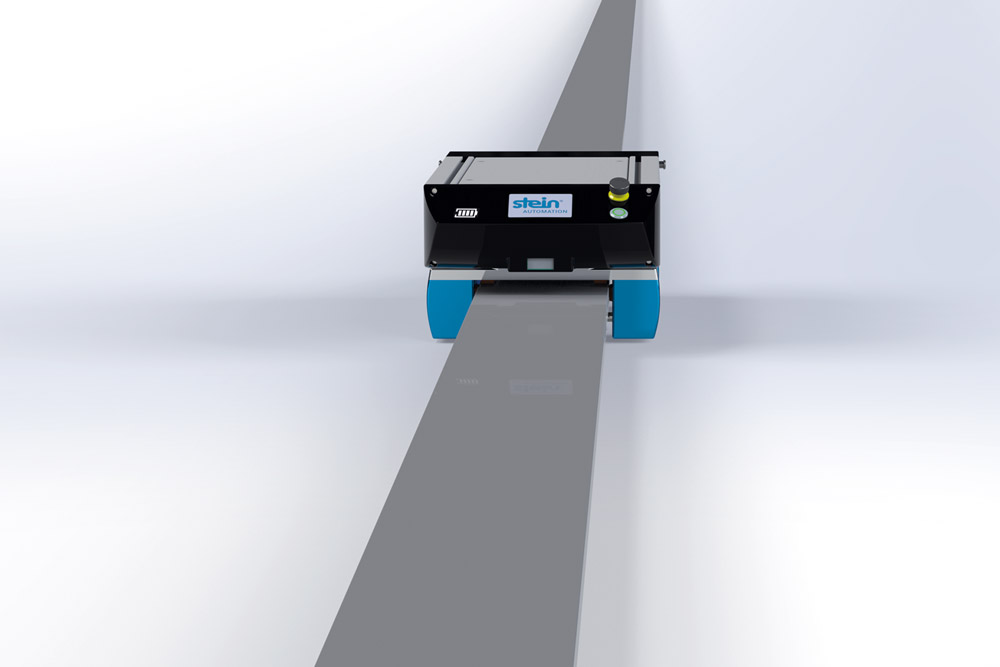

The STEIN link® track is extremely robust and stable, so that the shuttles can drive on it without the risk of tipping over and can reliably transport even large products from A to B. Thanks to intelligent sensor technology, the shuttles independently detect obstacles of any kind and brake gently. This ensures that your sensitive products are transported gently and without impact.

INTELLIGENT NETWORK

The STEIN link® Shuttles can communicate with each other decentrally, with sub-assemblies such as splitters or collectors, and centrally with the higher-level control system. This enables fast communication adapted to the situation. Thanks to intelligent workflow and order management, the shuttles reach their destination quickly and reliably. In addition, communication with third parties such as an ERP system is possible via the central control system.

The advantages of STEIN link

- Cost-effective transportation from A to B

- No wiring along the track – very simple installation

- Flexibility: easy adaption to higher output by adding shuttles

- Stable & shockproof transport

- Long distance transport – floor, on the wall or ceiling mounting possible

- Combines intralogistics AND assembly processes

- Fully automated battery management

- Intelligent routing, programmable workflows and order management

- Can be combined with STEIN conveyor systems

The STEIN link components

Shuttle

80 kg (176 lbs) payload per shuttle

Up to 50 m/min transport speed

Intelligent distance sensor technology

Transport of material directly on the shuttle,

on a pallet or in boxes (bulk material) possible

Shuttle dimensions L x W x H: 647 (25.5″) x 292 (11.5″) x 201,5 mm (7.9″)

(H: lower edge of profile to upper edge of shuttle without emergency-stop!)

24 V / 2,5 A power aux supply on the shuttle

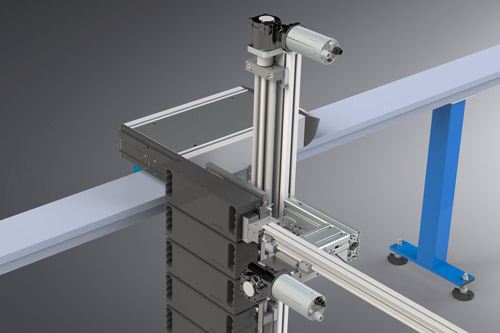

Track Profile

Integrated cable duct (clean, slim design)

Aluminum, extruded profile, natural anodized

Profile grooves for mounting material

Maximum module length: 5,000 mm (197″)

Width 160 mm (6.5″) x height 70 mm (2.8″)

Hight of the track profile is freely scalable

Ceiling mounting possible

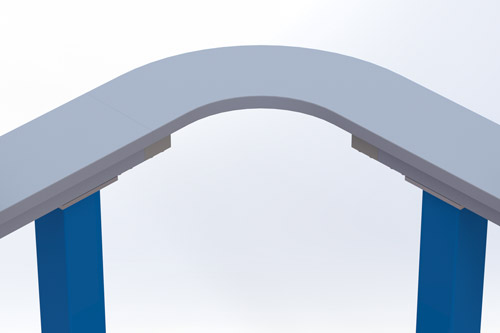

Curve

Radius of the track 250 mm

Pure mechanics – no electronics

Standard angles: 90º /45º

By stringing them together a 180º curve

is easily possible

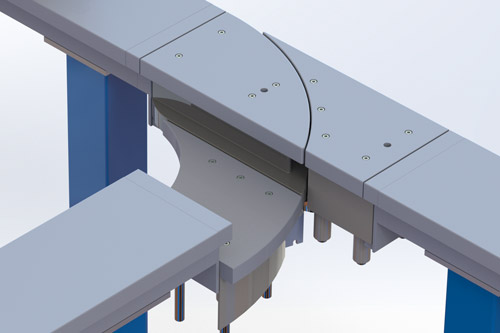

Track switch

Inlet and branching module

Radius of the track 250 mm

Track changing time 8 s

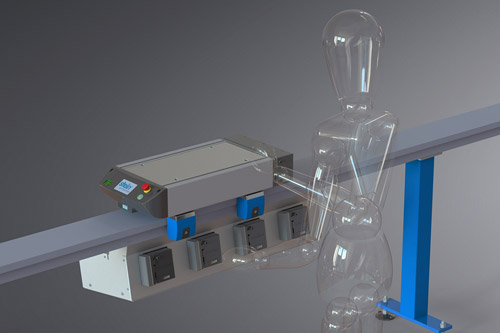

Fast & easy battery change

The STEIN link® Shuttle is equipped with an exchangeable battery. This means that no cabling is required along the track and makes installation particularly easy. Thanks to the optional manual or fully automatic changing station, the battery can be changed quickly and easily during operation.

The capacity of the battery changing station can be adjusted depending on the number, route and running time of the shuttles.

Manual battery exchange

Automatic battery exchange

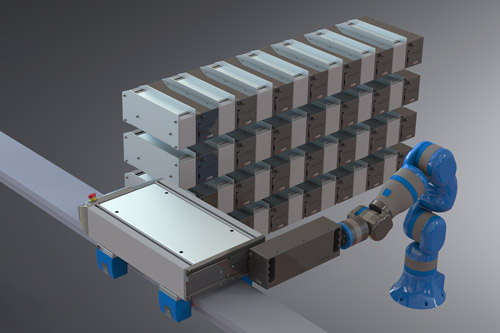

Battery exchange with a robot

Advantages of an exchangeable battery as the main power supply

-

Shuttle is independent of charging station

-

Fast & easy battery change

-

Charging time has no influence on cycle time

-

Low-maintenance power supply

-

Reduced installation effort (no wiring)