The home of quality

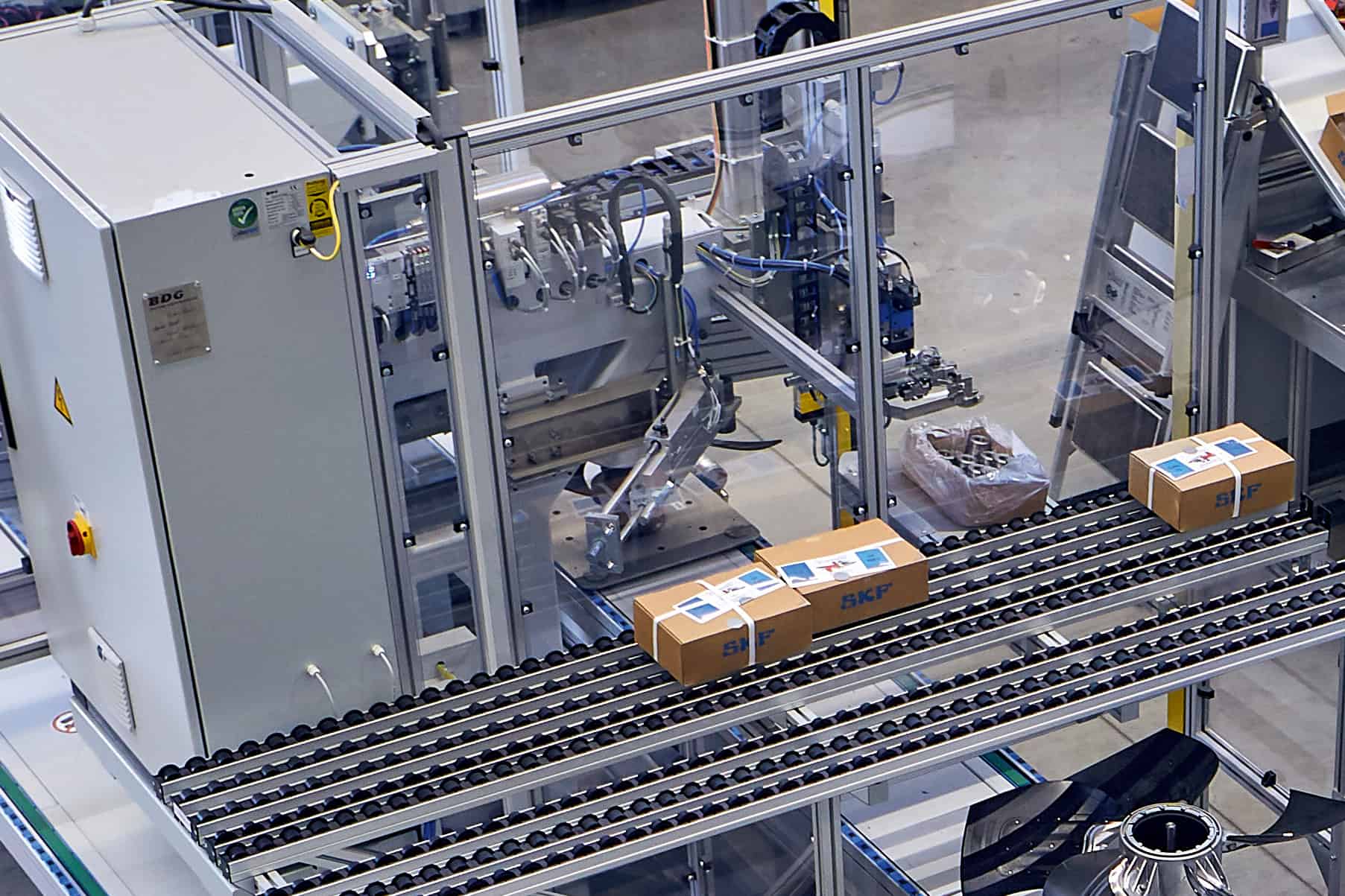

Assemblyline transfer systems are our passion and strength. We want to accompany our customers’ workpieces along the assembly line as intelligently, carefully and safely as possible.

Automation and logistics for the industry of tomorrow

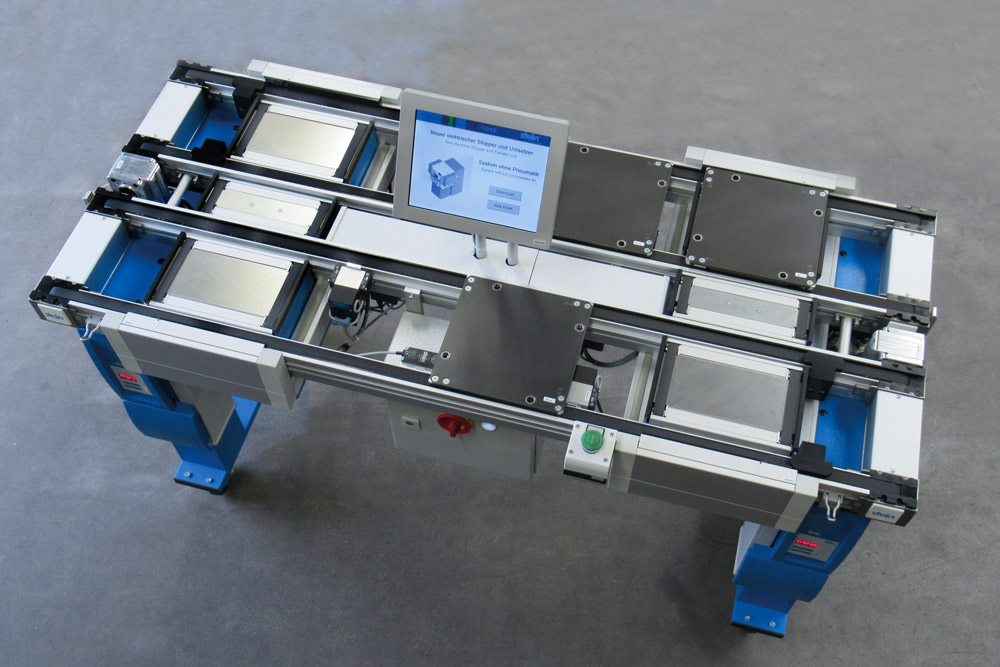

STEIN LEAN

STEIN 300

The STEIN 300 has a fixed place in over 3,900 assembly halls. With a vast range of customers and in a wide variety of configurations.

STEIN 300e

Instead of pneumatics, the stoppers, transfer units or centering devices are controlled via electric drives.

STEIN 400

STEIN Control

Experience and service go hand in hand for us

Industries

Systems

Meters of conveyor

Continuing a good tradition

We believe that serving our customers not only means providing them with expertise and powerful solutions, but also means cultivating long-term, collaborative relationships sustained by mutual trust. With our stable base of regular customers and motivated, long-serving employees, our future looks bright.

Where are we strong? Transfer to the future

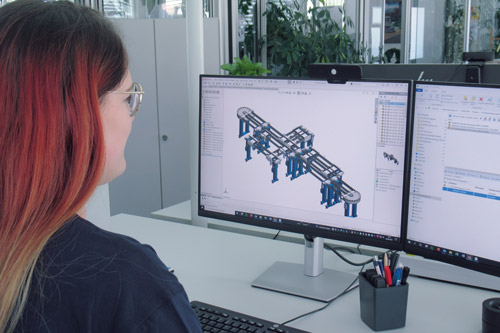

Flexible

Components are delivered within 4 to 6 weeks

Including STEIN CONTROL within 10 to 12 weeks

Easy

STEIN CONTROL achieves great things whilst remaining absolutely transparent and easy to use. As a result, after a brief introduction anyone can assign schedules for different product variants. Orders and schedules are easy to configure You work with the proven STEIN Standard > 3,900 plants

Efficient

Horizontal communication ERP/MES-connection

Batch size 1, mixed production up to the Boomerang Workflow

+49 7728 64485 - 0

Johann-Liesenberger-Straße 7

78078 Niedereschach

Germany

Contact

Write to us, because together we can achieve a lot.