STEIN LEAN

simply chainedWe are proud that STEIN not only has experience with LEAN PRODUCTION, but has also contributed to its success: Already in 2009 one of our customers won the Automotive LEAN PRODUCTION Award in the category “International Medium-Sized Businesses”.

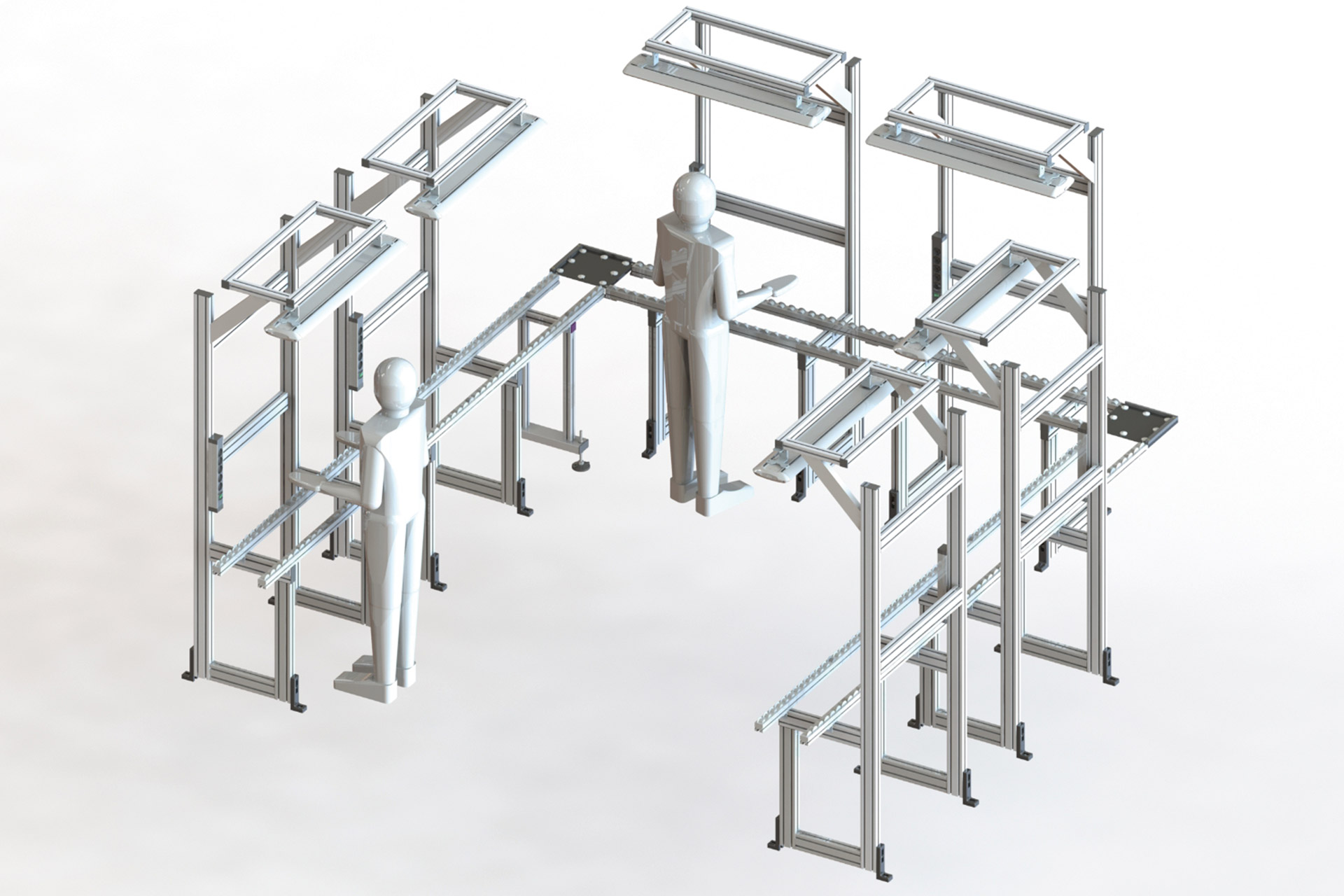

Solution variants

STEIN Components

Stein 300 with individual components is the basis for successful production. To allow customers to go their own way when realising their installations, all components and corresponding data are available in the ‘toolkit’. Plant designers and engineers can use them to create custom solutions with all the possibilities of STEIN technology.

STEIN assembled

STEIN 300 ASSEMBLED is a good choice for anyone wanting to order an installed system rather than individual components. Savvy planners can configure a system themselves, whilst STEIN assembles the individual components and delivers a system that is virtually ready to use. Controlling the system with software and hardware is left to the customer.

STEIN CONTROL

What can LEAN PRODUCTION do?

The method known as “STEIN LEAN” is used where material is to be continuously processed from the beginning of a production process to the end in a single flow, to the extent possible. This also makes it possible to react flexibly, in the event of errors, and to interrupt the production process quickly so that no further bad parts are produced.

STEIN LEAN in Action

The right modules

Of course, basically all components of the proven STEIN 300 can be used in a lean production version of the system. The most common components, which meet the basic needs of LEAN PRODUCTION are however the following:

- manual roller track or driven belt section

- manual workstation

- roller table

- centring unit